- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

TX2-160 industrial robot

Our fast and precise TX2 industrial robots are the next generation of 6-axis robotic arms. This line of robots provides the ideal combination of speed, rigidity, size and precision. These robots have unique features that make them adaptable to all industries, including sensitive environments.

Optional SIL3 / PL e safety functionalities allow high productivity thanks to more compact yet performant cells.

The TX2-160 has a payload of up to 40 kg and a maximum reach of 2010 mm.

Main features and benefits

- Conception

- Integration

- Performance

- Safety

- Reliability

- Connectivity

Sensitive environment versions

Contact our specialists or get more technical information

TX2-160

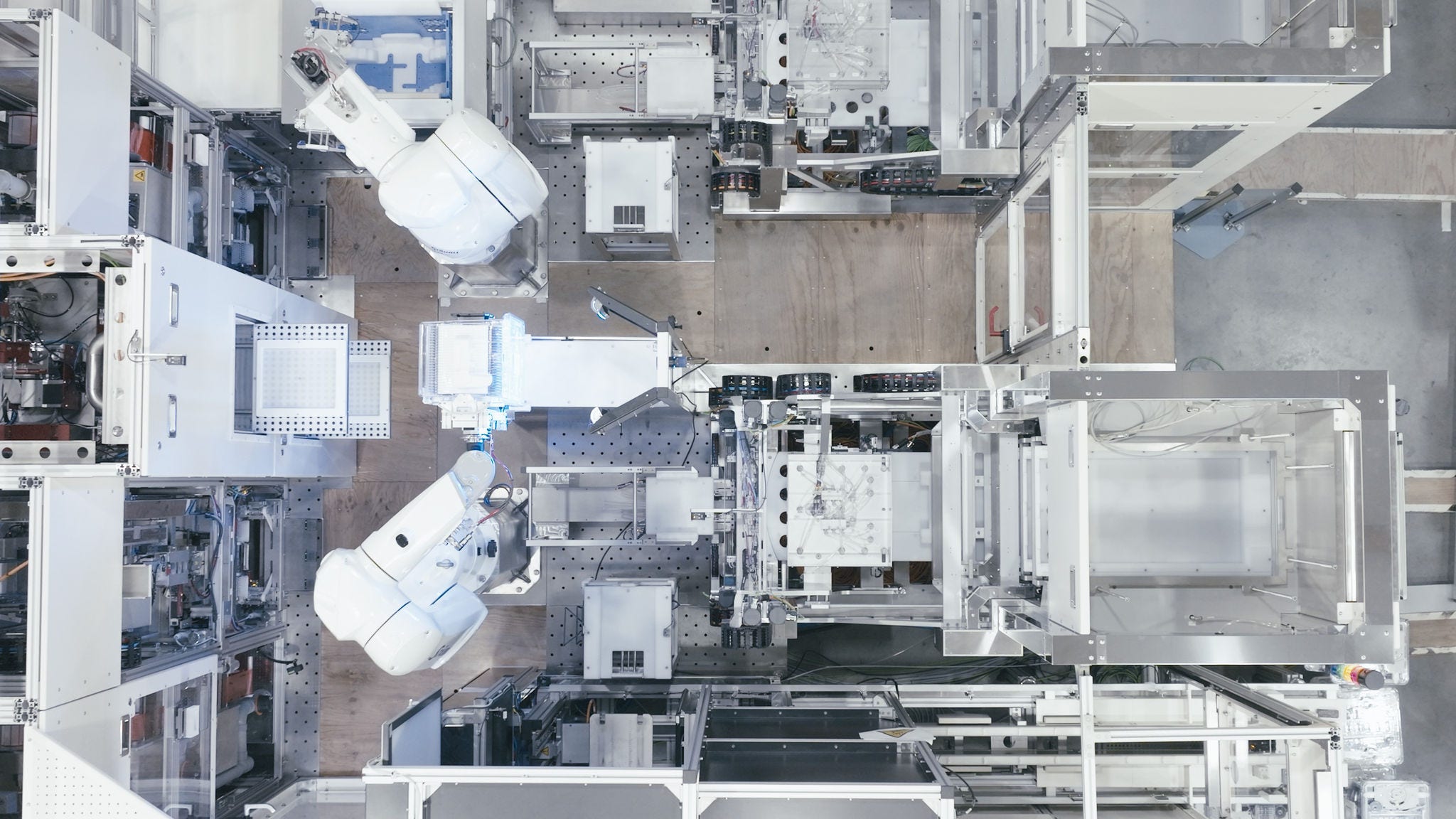

Application examples at customer sites

-

Safe transport of wafers to the FABs

Getting wafers to the fab safely is tricky business. To ensure that this valuable freight arrives undamaged, the front opening shipping boxes (FOSBs) are double-bagged in an intricate process. A Bavarian company has fully automated this complex sequence of steps, integrating two Stäubli cleanroom robots into its packaging line. -

Welding robot for two cells

A supplier that manufactures custom components in small to medium quantities has made exactly the right choice with a Stäubli robot. Thanks to a linear axis, the laser welding robot can work in two cells and drive maximum productivity.