- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Payload up to 20 kg

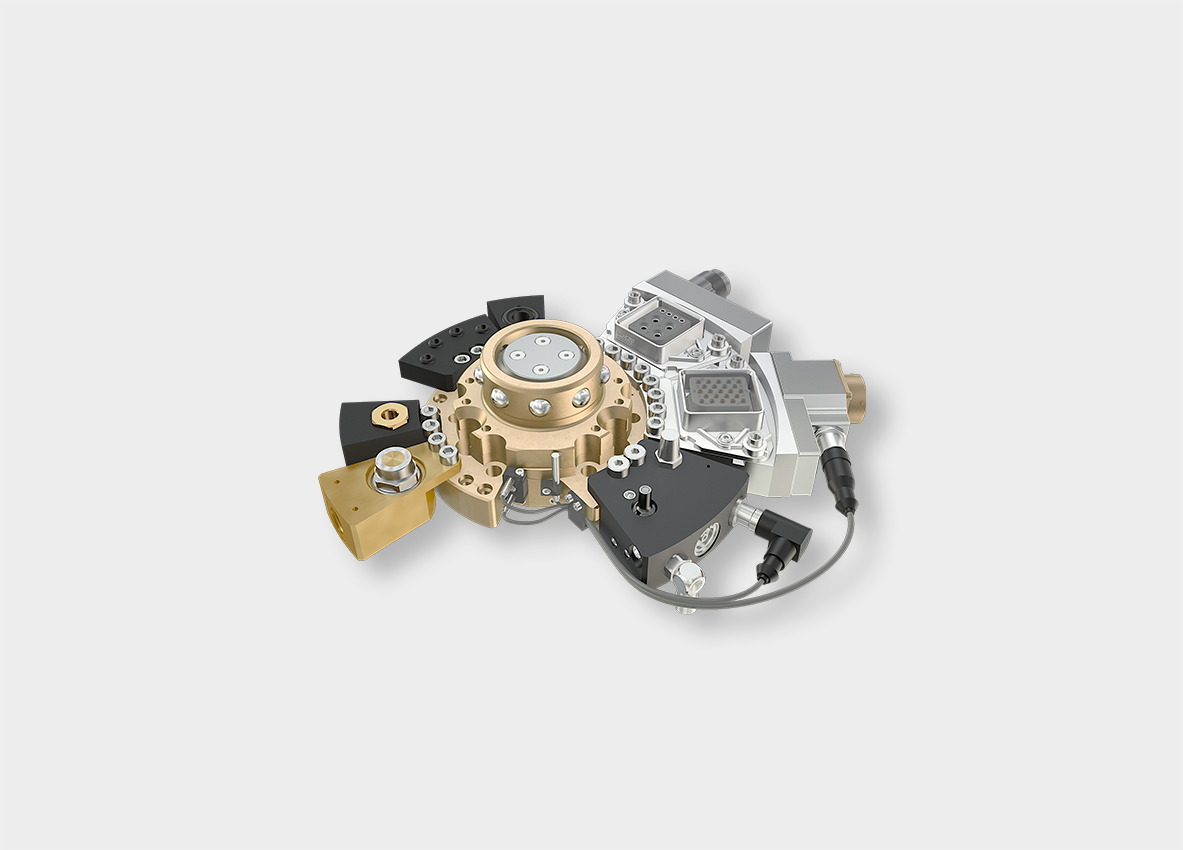

Robotic tool changer MPS 025

The MPS 025 is a compact and reliable robotic tool changing system designed for low payload applications. With a payload capacity of up to 25 kg, this automatic tool changer offers impressive precision and repeatability, with a repeatability of +/- 0.0015 mm and the ability to handle maximum static and dynamic moments of up to 70 Nm and 255 Nm, respectively.

The robot adapter flange features an ISO 9409-1-40-4-M6 pitch diameter, making it compatible with a wide range of robots and small payload applications. The MPS 025 is designed to operate in harsh environments with an operating pressure range of 0.45 - 1.0 MPa and an operating temperature range of 0C to +50C.

This robotic tool change system is highly flexible, with numerous module variations available for various media, data and power transfer components, such as pneumatics, vacuum and cooling, signal and power supply, and primary power. Its compact and modular design also makes it easy to adapt to specific application requirements.

The MPS 025 offers remarkable precision and reliability, making it an ideal choice for various small payload applications that require automation of the tool change process.

APPLICATION

- Automotive manufacturing

- Electronics manufacturing

- Food and beverage production

- Medical device manufacturing

- Aerospace manufacturing

- All types of assembly lines and material handling

Repatibility:

+/- 0.0015 mm

Payload:

up to 20 kg

Max. static moment:

34 Nm

Modul places:

4

Robotic tool changers - modular solutions for every requirement

Whether your projects have individual and comprehensive requirements or need a fast solution, Stäubli's range of robotic tool changers can quickly meet all complex demands thanks to the modular product concept.

Technical specifications

| MPS 025 | |

| Payload | 20 kg |

| Max. static moment (Mx/My) | 34 Nm |

| Max. static moment (Mz) | 34 Nm |

| Max. dynamic moment (Mx/My) | 119 Nm |

| Max. dynamic moment (Mz) | 119 Nm |

| Operating pressure | 0.45 - 1.0 MPa |

| Operating temperature | 0 °C - +50 °C |

| Repeatability | +/- 0.0015 mm |

| Height (coupled) | 46 mm |

| Pitch circle diameter (PCD) robot adapter flange | ISO 9409-1-40-4-M6 |

| Module places | 4 |

MODULES AND ACCESSORIES

- Transmission Modules

- Tool stand

- Teaching aid

- Safety+

Transmission Modules

- Pneumatic & vacuum module FTM

- Pneumatic module ROK

- Ground Pin Module

- Tool coding module

- Electric module for signal and data transmission M8/M12

- Giga module

- RFID module

Tool stand

- Flexibility: With the single system components, your own individual storage solutions can be compiled and also easily integrated into existing systems.

- Modularity: Choose between preconfigured complete systems or single modules that can be used directly with standard profile solutions.

- Longevity: The floating bearing in the upper part of the system ensures that the tool is optimally held in the drop-off position. The load on the components is minimized.

- Economical: One tool storage system that can be used as a vertical or 90 ° rotated solution offers a wide range of possible uses.

- Process reliability: A mechanical fixation with adjustable retention force enables additional securing of the dropped -off tools. The system can optionally be expanded with integrated sensors for status indication.

Teaching aid

- Simple installation of programming support with a click function

- Quick and easy determination of coupling position

- Exact positioning for quick and fault-free docking processes and a long service life

- No additional software necessary

Safety+

System for personal and system safety.