- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Spot welding connectors for highest performance in body shops

Spot welding is the most applied resistance welding process for joining sheet metals. It is the predominant joining process for assembling car bodies and large components in the automotive industry. Recognized by most vehicle manufacturers, tier ones, and their suppliers as the international standard in automotive body shops, Stäubli Electrical Connectors (previously Multi-Contact MC) has been established for decades.

Serving major global players in Body-In-White (BIW) applications, our welding power connectors help you reduce downtime during production, as well as installation and maintenance costs. Compact in size and high in performance, our resistance welding solutions for primary and secondary circuits guarantee optimal power supply to welding units and can be easily integrated into modern light-weight manufacturing concepts. No matter whether steel or aluminum sheet metal components. User-friendly during production maintenance, our tried and tested quick disconnects will grant reliability and safety to your welding process from sub-assemblies to the final vehicle body.

Using plug connectors instead of bolted connections minimizes connection time and maintenance, which reduces production downtime. In the context of the automotive industry: every minute saved means one more car produced.

In addition, Stäubli's spot-welding connectors reduce set-up costs and therefore successfully contribute to a lower TCO compared to conventional solutions. While bolted (hard-wired) connections require highly skilled personnel to install, Stäubli spot welding solutions are safe, user-friendly and can be connected with minimal training.

All our spot welding connectors benefit from the unique performance of the proven MULTILAM Technology. It features unmatched electrical and mechanical properties and scores with excellent performance due to first-rate and constant current-carrying capacity as well as minimal transition resistance. The sophisticated construction technique of MULTILAM with specially formed and resilient contact elements guarantees a long life span thanks to low resistance and heating.

Energy efficiency for sustainability in production

The quality of a plug connector is determined by the sum of the resistances Rtotal (Rcrimp1 + Rcrimp2 + Rcontact). The lower the overall resistance, the smaller are the power losses Pv in the plug connection. Small power losses are characteristic of an efficient, environment-friendly connector.

Comparison Stäubli/Ordinary connector suppliers:

The automotive industry relies on our high-efficiency connections for spot welding applications in production lines where our connectors guarantee safe and reliable power supply to welding units.

Featuring both high current-carrying capacity and unparalleled contact reliability, our spot welding connectors are the foundation of consistent quality on every single weld.

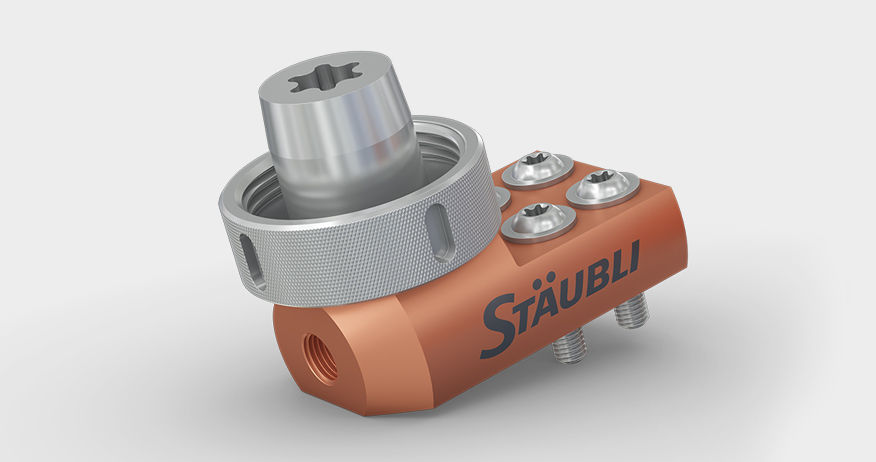

Our spot welding connectors are a combination of extremely compact design with superior performance.

Not only are our connectors resistant against welding fumes/weld spatter and offer IP67 protection, the RobiFix product family also offers a very light and compact design to easily integrate into all applications.

-

Primary circuit - Circular

With up to 5 poles, our circular range is designed to supply power to resistance welding units and can cover any application in spot welding. -

Primary circuit - Flat

With 3 poles in line, the RobiFix family ensures safe power supply to spot welding units. It has become the global standard in automotive body-shops. -

Secondary Circuit

The modular and scalable SpotFix connect system was specifically developed for use in the secondary circuit of resistance welding equipment, particularly X-guns.