- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

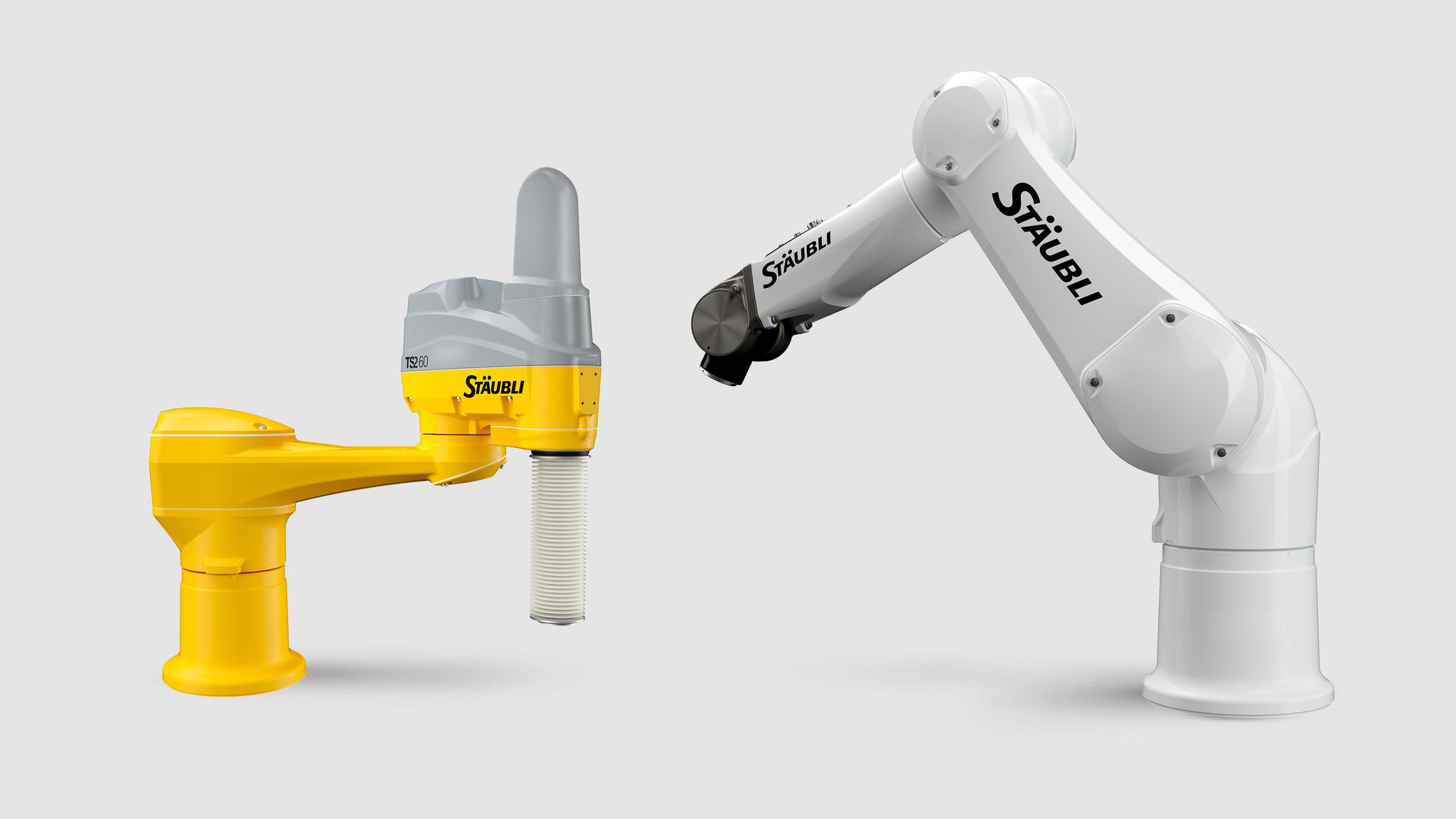

The spectacular growth for battery demand challenges gigafactories investments in their time-to-market capabilities. While production quality remains a necessary differentiator, line flexibility becomes a critical requirement to enable future product evolutions. As a result, Stäubli SCARA range is leading electrode stacking processes with major worldwide players. The whole robot range is also extensively used in downstream operations, in assembly and inspection.

The advanced automation knowledge from Nordfels and the deep welding expertise from Voltlabor (powered by Miba Group), delivered an amazingly efficient solution to lithium-ion battery modules assembly. The VOLTJET is a fully integrated cell, containing multiple inspection points and full traceability with the ability to process up to 100kWh battery capacity per hour. It uses Stäubli high-performing and repeatable robots for the cylindrical battery cells testing and assembly processes with a proprietary laser welding technology to form the battery module.