- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

Pushing the limits of the technically feasible

The production of sensor modules for diesel engines requires highly sophisticated automation solutions capable of handling ultra-miniaturized components. At its Bamberg, Germany plant, Bosch is working to meet this challenge with high-precision robots and an intelligent service strategy.

CUSTOMER BENEFITS

- Process-reliable automation of the most demanding assembly steps

- Intelligent maintenance concept

- High-precision robots with superior drive technology

- Reliable compliance with ultra-short cycle times

- Systematic documentation and traceability

TASK

Highly complex precision assembly of sensor modules

At Bosch Bamberg, sophisticated assembly processes for miniaturized components play a central role in the production of the common rail injectors, nozzles and sensors that go into the injection systems of diesel engines. Core manufacturing processes also include the assembly of sensor modules. This complex process places the highest demands on robotics and calls for a novel service strategy.

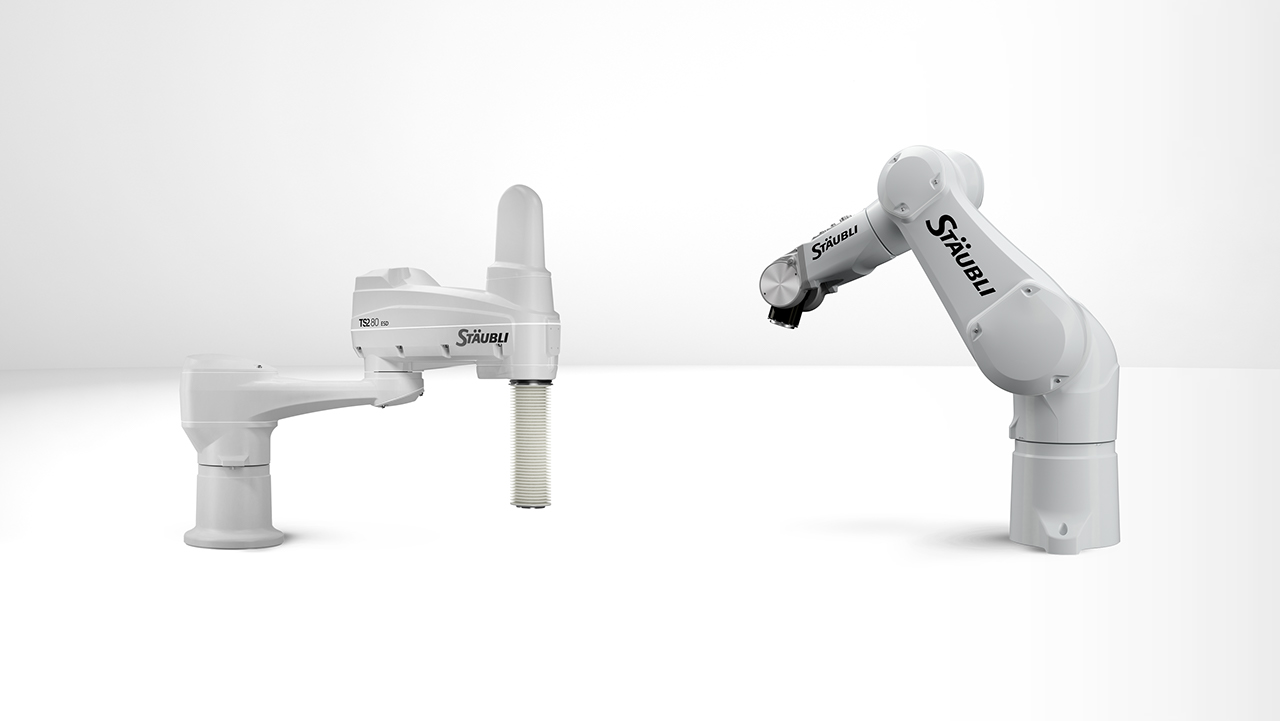

Even a cursory look at the rotary indexing table, where assembly as well as quality assurance take place, illustrates the complexity of this cell. Five Stäubli robots and 18 visual inspection systems are installed in a very confined space, three of them on NC axes that give the cameras mobility.

The assembly nests of the rotary indexing table are loaded with the relevant components by high-speed, high-precision Stäubli TX2 six-axis robots. The parts are conveyed to the cell by automatic feeders. Cameras communicate the exact gripping positions to the robots. The precise placement of the tiny components in the nests of the rotary indexing table is also monitored by camera. This means that, even at the initial stage of populating the rotary table, every move is thoroughly monitored and documented to ensure zero-defect assembly.

SOLUTION

Extreme requirement: A repeat accuracy of under 10 µm

Every single assembly step places high demands on automation, but the last station on the rotary indexing table required a very special solution. This is where the housing, with a diameter of less than 10 millimeters, has to be lowered over and attached to the fully assembled sensor unit. In the process, the 0.6 mm thin contact pins have to be guided through the openings in the housing. The precision required of the robot in this process is under 10 µm.

The assembly task described here might ordinarily rule out the use of robots in the cell, because an accuracy of under 10 µm is not achievable by any series-production robot, not even the high-precision TX2-40 which Stäubli credits with a repeatability of ± 20 µm. However, the Stäubli TX2 robot’s first-class JCS drive technology allowed the enhanced precision to be achieved by means of targeted fine-tuning.

Specially adapted maintenance concept

The exceptionally high precision also means that normal maintenance routines would not be appropriate. If servicing was done on only a standard annual basis or in the event of an unplanned intervention, the precision would be lost. The robot would have to be completely recalibrated – which can only be done in-house at Bosch on a special measuring system.

In order to be able to respond quickly in circumstances where service is required, Stäubli and Bosch jointly developed a customized maintenance concept. Bosch keeps a robot of identical design on hand, which is first serviced at Stäubli. Next, the gears are precisely adjusted and measured using laser technology. The robot is then precision-optimized at Bosch. It is consequently ready for immediate use at any time.

- teaser

- teaser

- teaser

CUSTOMER USAGE

Process-safe assembly in a compact space

After a precisely defined maintenance interval, the two robots are swapped. This creates the prerequisite for uninterrupted and process-reliable quality production.

Other features of the sensor assembly station include an exceptionally compact design and ESD compliance of all components, including the robots. After all, the electronic components assembled here operate with low voltages and currents and are correspondingly sensitive.

The use of Stäubli robots at the Bosch plant in Bamberg is by no means the exception. Stäubli robots are always the preferred option here. And this has also proved to be the case with this extraordinary system, which performs better than any high-precision robot should be capable of. With this assembly system, Bosch and Stäubli have broken new ground and demonstrated how working in partnership can push the limits of what is technically feasible. As a result of this collaborative venture, the system runs stably and highly productively with an extremely low error rate, despite the exceptionally demanding precision specifications.