- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

FOOD INDUSTRY

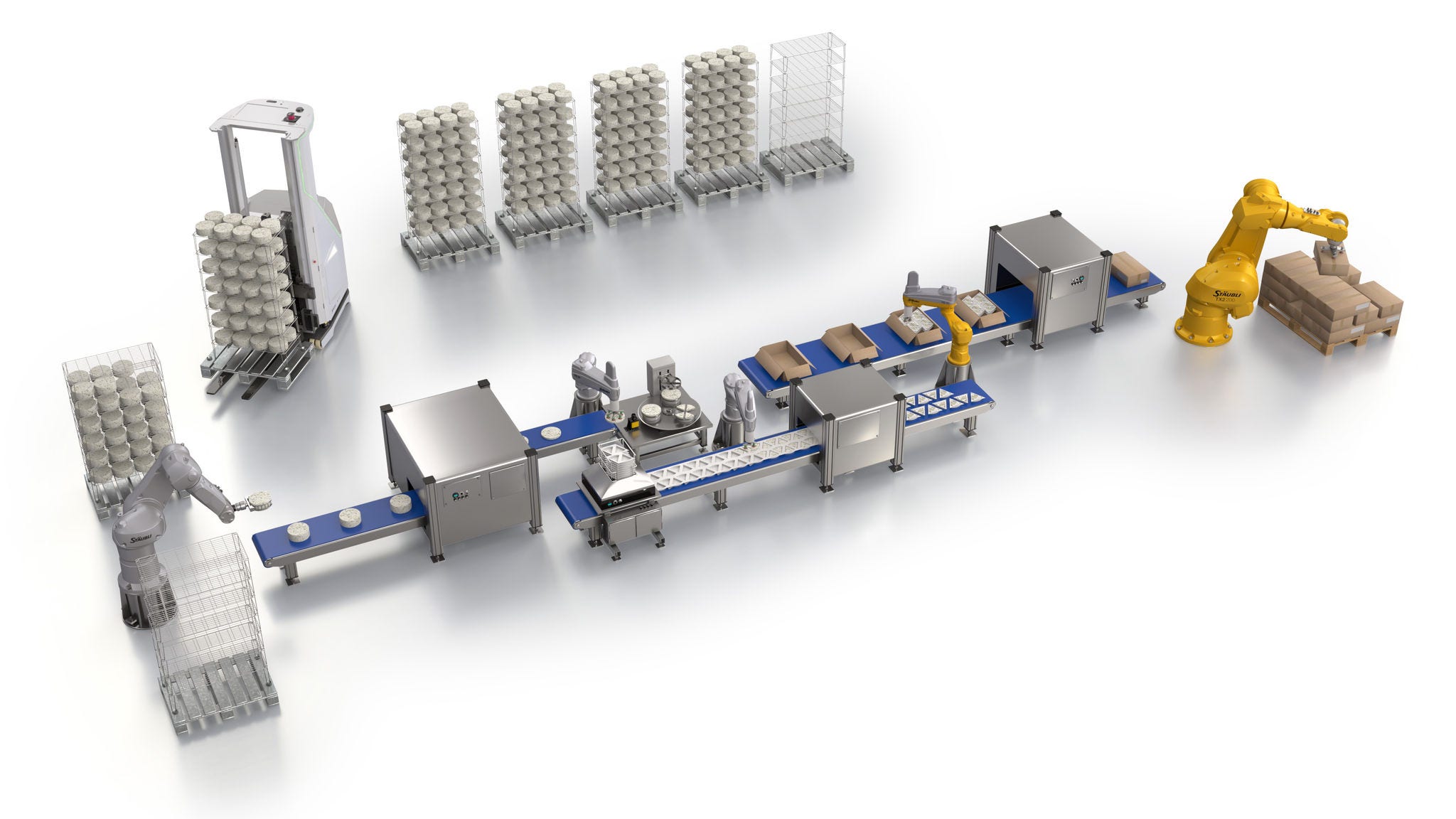

Robot-assisted production of dairy products

Industrial cheese production presents several challenges: direct contact with unpackaged food, the highest hygiene standards, and regular rigorous cleaning procedures. From delivery to processing and packaging, Stäubli offers perfectly matched solutions for safe, flexible automated production of dairy products. Benefit from the innovative capacity of a technology leader and our extensive experience in the cheese processing industry.

Main applications from primary processing to packaging

- Hard Cheese Production

- Hard Cheese Production (2)

- Fresh Cheese Production

- Soft Cheese Production

- Soft Cheese Production (2)

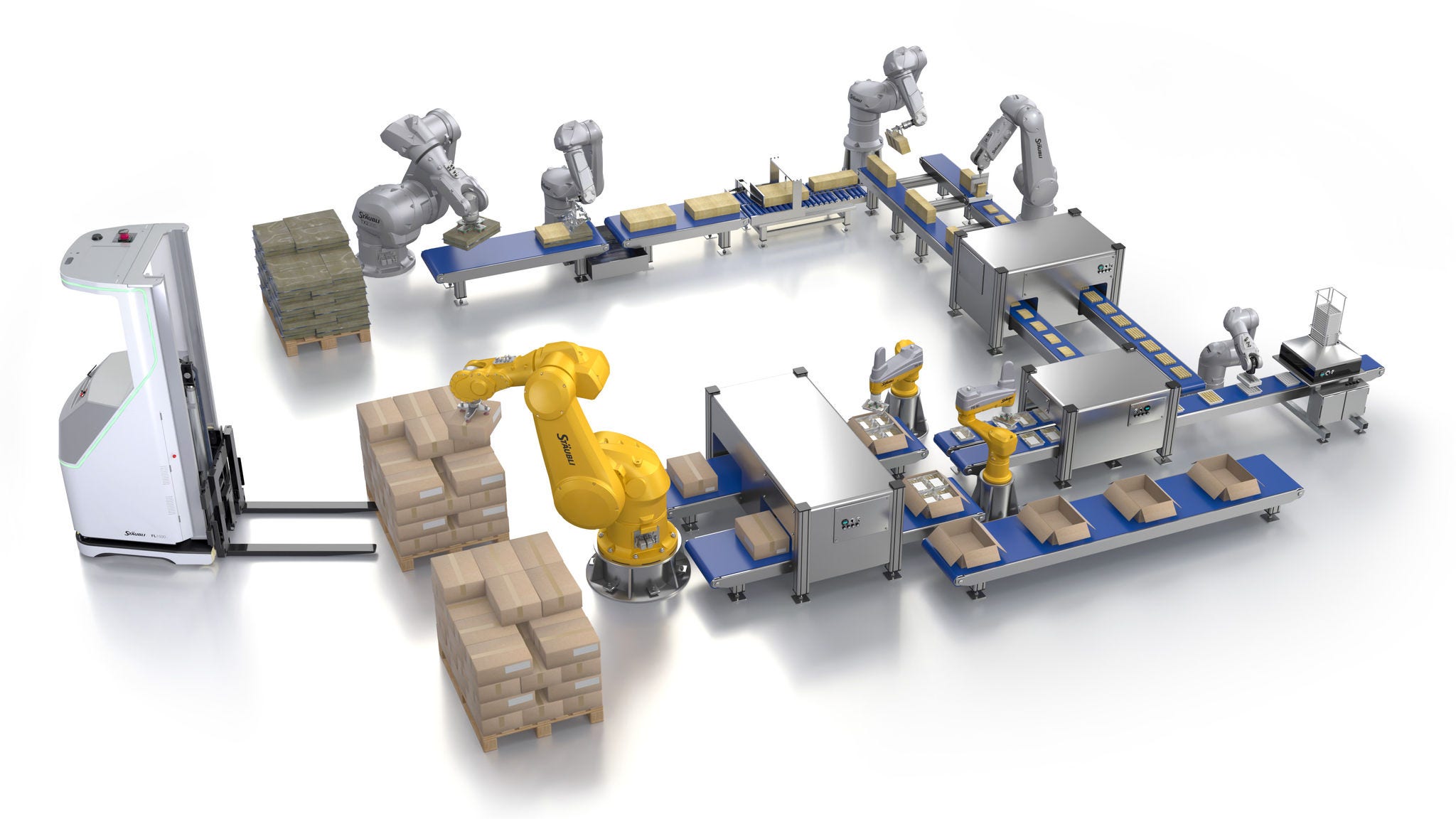

Their performance, as well as their exceptional hygienic properties in terms of dynamics and precision, make Stäubli HE robots the first choice for the production of hard cheese. The extensive portfolio of four- and six-axis robots ensures that every process on a hard cheese production line can be systematically automated with Stäubli robots.

From the infeed of “Euro blocks” or cheese wheels through all processing steps such as dividing, cutting and portioning, to primary and secondary packaging with subsequent stacking on pallets, Stäubli robots ensure ultra-efficient hard cheese production.

Additionally, Stäubli WFT’s highly flexible AGV solutions convey the finished pallets to the warehouse or directly to the shipping department without human intervention.

The process begins with a TX2-200 HE lifting the cheese blocks from a pallet and depositing them on the conveyor belt.

A TX2-160 HE then unpacks the cheese block and removes the foil.

After the block has been cut, a second TX2-160 HE places the half blocks on two parallel belts.

Next, a TX2-140 HE divides them into portions with an ultrasonic knife.

A fully automatic cutting station.

A TX2-90 HE handles the primary packaging of the hard cheese portions.

Two TS2-100 HEs are responsible for the secondary packaging.

Finally, a TX2-200 stacks the filled and sealed cartons on pallets.

An autonomous counterbalanced stacker from Stäubli WFT takes the pallets to the warehouse or directly to the shipping department.

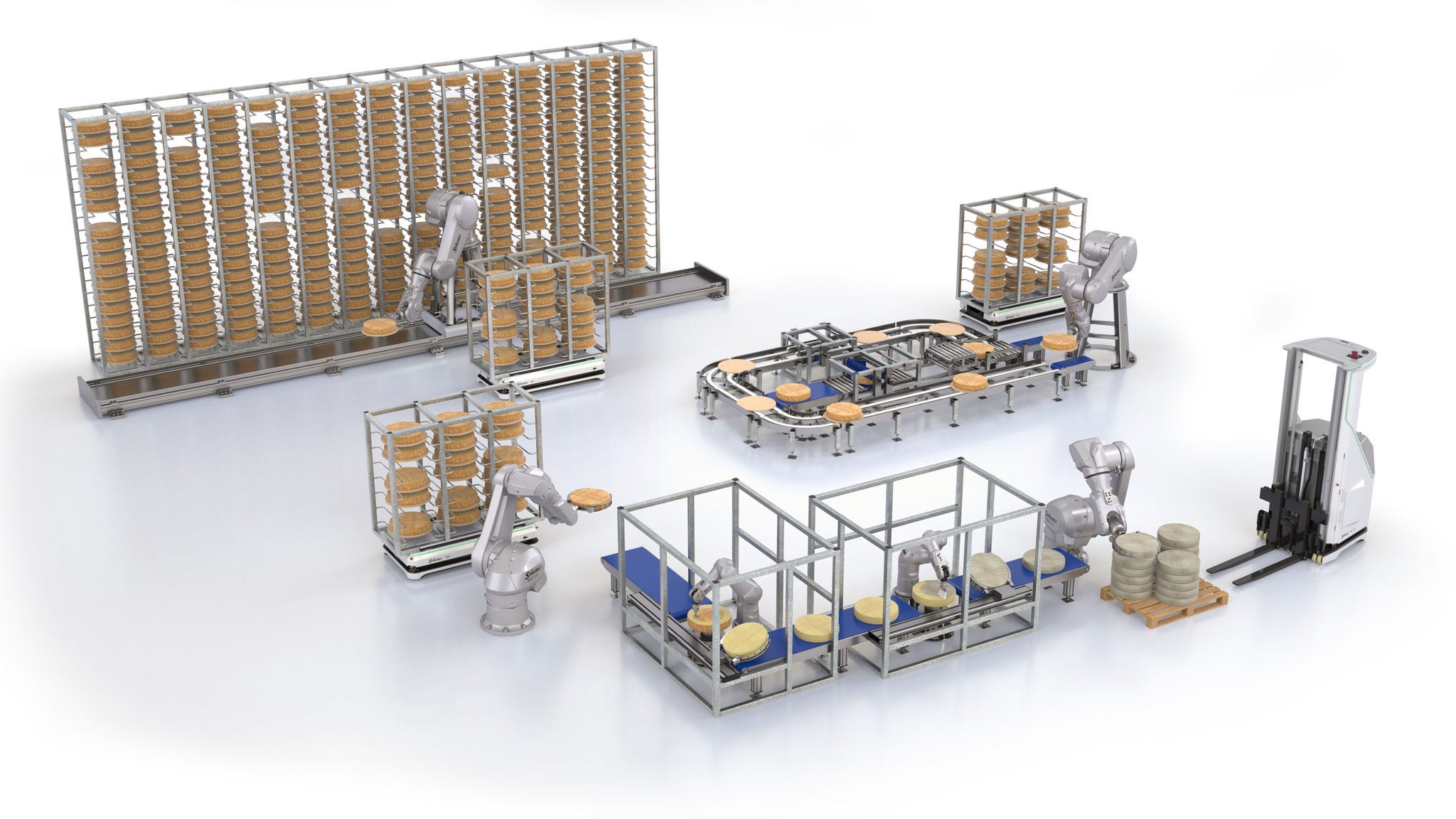

The Stäubli HE robots prove their worth not only in the execution of all process steps along the way from basic cheese wheel to sales packaging, but also in a variety of other tasks.

For example, these highly versatile machines automate cheese care systems, de-rind cheese loaves with laser cutting, and coat them with seasoning. In this way, they relieve human employees of strenuous tasks and become valued work colleagues of the future.

One major benefit for users is that Stäubli WFT’s advanced AGVs provide a full range of solutions, in which even the transport of cheese loaves between storage, process stations and the shipping department is automated.

A TX2-200 HE collects the cheese loaves from storage and places them on an AGV, which then takes them to the production line.

Another TX2-200 HE unloads the AGV and places the loaves on the infeed system to the de-rinding station.

A TX2-90 HE then shaves off the rind of the cheese with high-precision laser cutting, keeping waste to an absolute minimum.

For special types of cheese, a second TX2-90 HE can apply seasoning to the surface of the cheese wheel.

A TX2-200 HE then picks up the cheese wheels from the conveyor belt and stacks them on a pallet.

Finally, an autonomous counterbalanced forklift from Stäubli WFT drives away with the pallets.

A TX2-200 HE takes responsibility for the loading and unloading of a cheese care system. The transport of the cheese loaves is performed by an AGV.

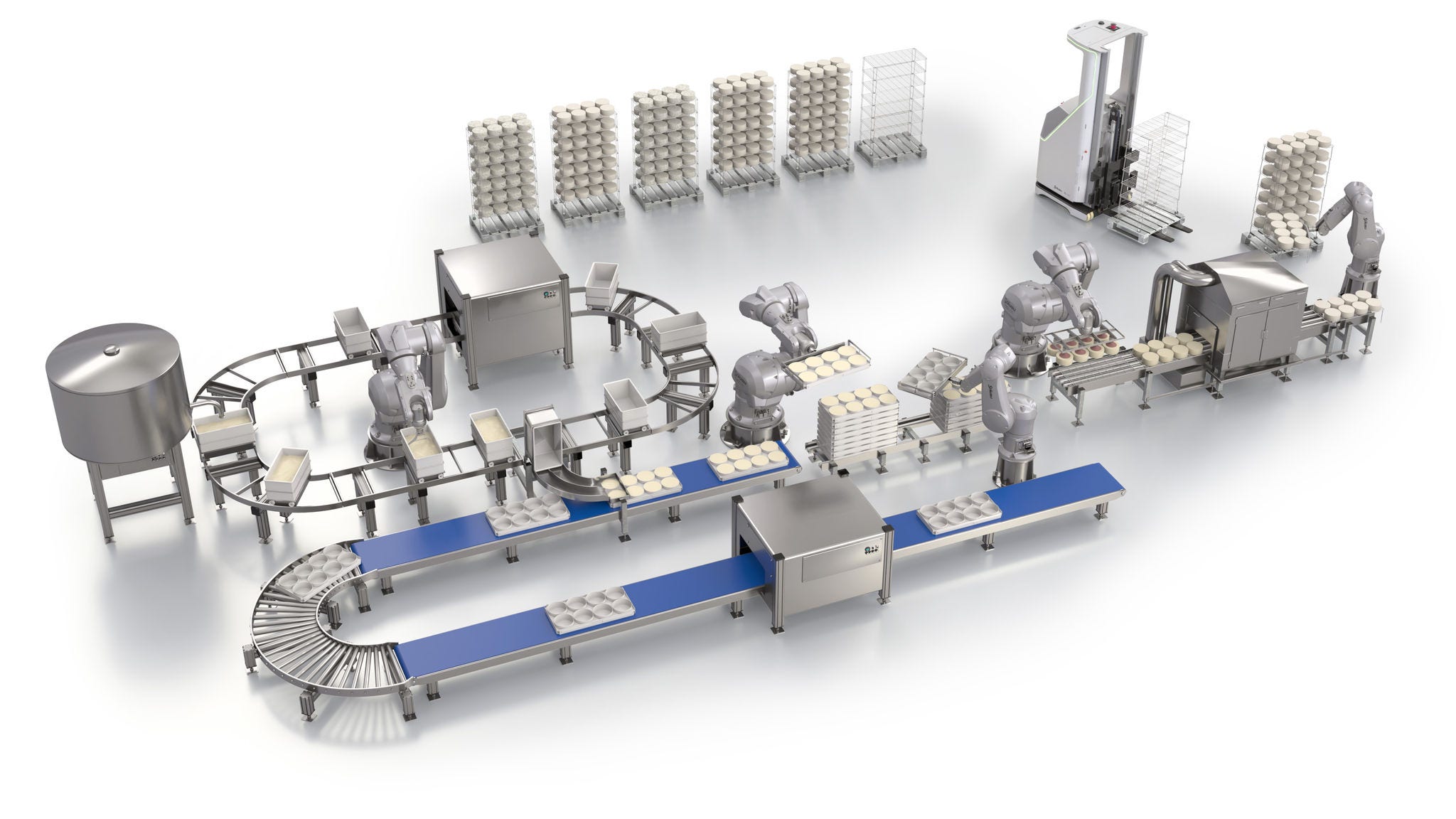

Stäubli robots in the HE series also meet the stringent requirements for the production of fresh cheese. Users all over the world appreciate these unique machines not only for their excellent hygienic properties, but also for their dependability.

For cheese producers, the deployment of robots delivers a high degree of flexibility combined with maximum product safety. The use of the highly dynamic Stäubli four- and six-axis robots lubricated with food-grade oil ensures the elimination of harmful contaminants.

A TX2-200 HE used in the preparation of curd in small tubs.

Handling of the filled molds and packaging is the task of a TX2-200 HE.

A TX2-140 HE is responsible for extracting the products from their molds and transferring them to the packaging station.

Even the SCARA TS2 models in secondary packaging are lubricated with H1 oil.

A typical application for the long-reach TX2-200: Stacking of cartons on pallets.

An autonomous Stäubli counterbalanced forklift delivers the finished goods to the warehouse or directly to the shipping department.

In the manufacturing of soft cheese products, too, more and more standard processes are being automated with Stäubli HE robots. The reasons for this are clear: greater flexibility, increased output and maximum reliability. The process steps are similar to those in fresh cheese production.

The robots start with the preliminary processes of curd preparation, take on the handling operations along the line, and manage the storage of the products in racks for further processing as well as loading the mold-washing machines – all of this being done safely, precisely and hygienically.

A highly versatile TX2-200 HE oversees curd preparation in small tubs.

Another TX2-200 HE handles the loaded molds after the filling process.

third TX2-200 HE extracts the cheeses from their molds and transfers them to a dry salting machine.

After salting, a TX2-160 HE loads the products into prepared racks.

A Stäubli AGV stacker subsequently takes the racks away.

A TX2-140 HE removes the empty molds for cleaning.

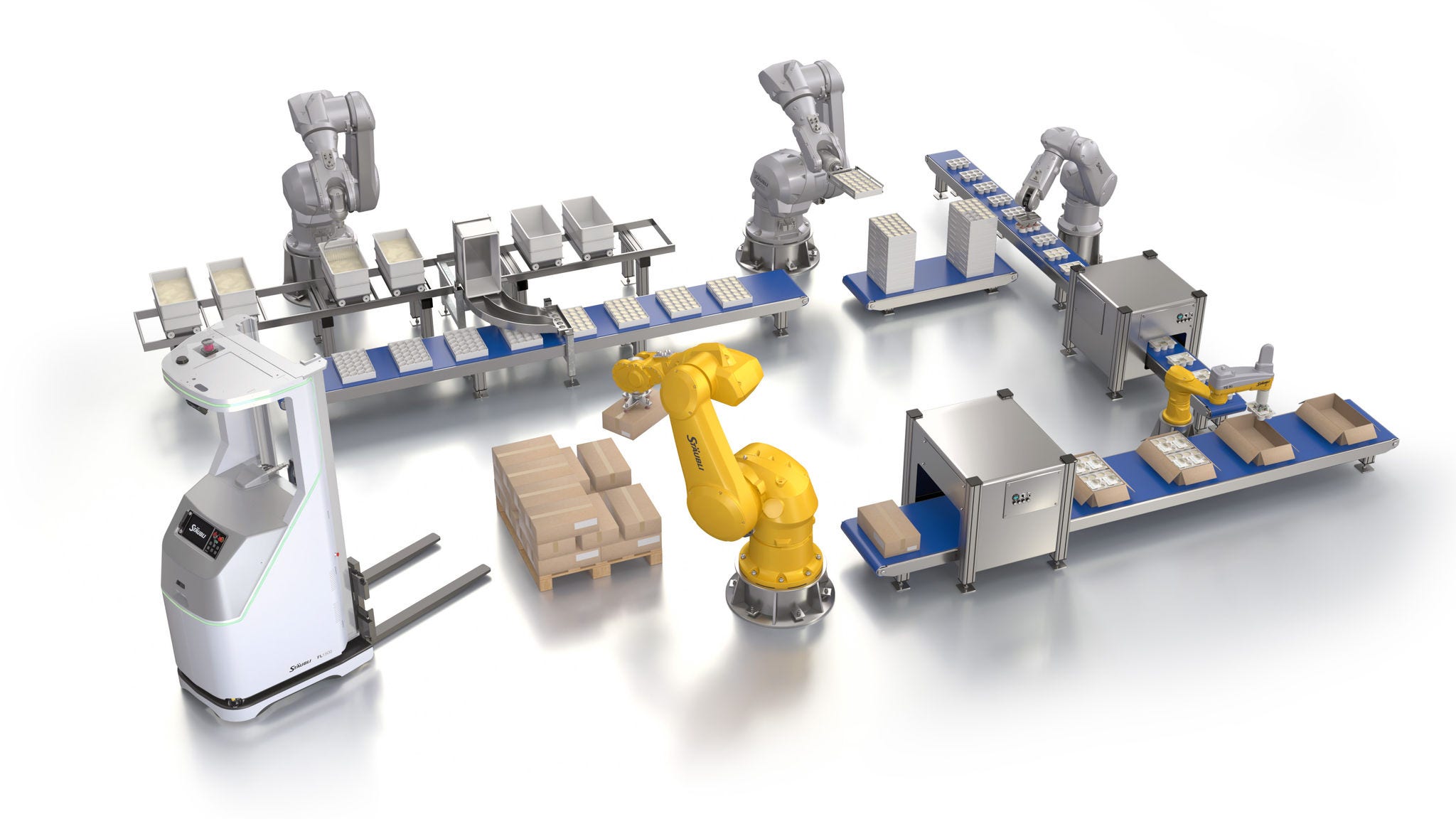

A production line for blue cheese offers yet another prime example of how the finely tuned Stäubli portfolio of AGV stackers along with four- and six-axis robots in the Humid Environment (HE) specification can be used to implement groundbreaking automation solutions.

The production line also shows that Stäubli Robotics can provide a precisely matched robot for every task. While SCARA robots equipped to HE specification are used directly upstream and downstream of the cutting process, a large standard version SCARA TS2-100 is used for secondary packaging.

A self-driving AGV stacker from Stäubli WFT delivers the racks to the production line.

Unloading and placing the cheeses on the infeed conveyor belt is handled by a TX2-160 HE.

The cheeses arrive at a TS2-80 HE, which transfers them to the cutting station.

After the cutting process, another TS2-80 HE attends to the retail packaging of the portioned cheese pieces.

Next a large SCARA TS2-100 places the packages into a cardboard box.

Finally, a powerful TX2-200 stacks the cardboard boxes onto a pallet.

Success stories

-

Soft cheese production

Robots have a long history in cheese production. However, a robot line that can handle six tons of unpackaged soft cheese per hour is a true innovation. This was implemented in a large dairy in Argentina – using Stäubli robots. -

Hard cheese production

In hard cheese production at BMI (Bayerische Milchindustrie eG) in Jessen, Germany, two robotic cells ensure hygienic primary packaging of freshly produced cheese blocks. Read how reliable, economically flexible and sustainable the packaging of 35,000 tons of hard cheese a year can be with the use of robots. -

Automatically derinding cheese wheels

Manual derinding of cheese wheels is among the most difficult and time-consuming tasks. With a brand-new system, the Dutch DERO GROEP sees the issue differently: Here, two robots have taken over this job and are four-times faster than the strongest employee. -

Curd preparation

ALPMA has developed a “bassine technology” for producing soft cheese. The special shape of the plastic vats, combined with a patented cutting process using a TX200 HE robot, slices curd with very little waste. -

Ice cream filling

Big Drum Engineering GmbH uses Stäubli TX90 HE robots to manufacture equipment for ice cream packing and filling operations. They are ideally suited for the hygiene processes in place at the company. -

Packaging of tubs

Six Stäubli robots – more specifically four SCARAs and two large six-axis machines – are dispatching a Czech dairy delicacy in record time. The speedy sextet manages the entire secondary packaging process, including palletization, of an amazing 20,000 tubs per hour. -

Automated derinding of cheese

Using continuous path tracking, a Stäubli TX2-90 HE robot de-rinds and coats irregularly shaped blocks of cheese in a Tyrolean organic cheese dairy. At least twice a week, intensive basic cleaning is required, which no other robot would survive. -

Automated Care of Emmental cheese wheels

The Leupolz farm cheese dairy is setting standards with an innovative cheese care system. A powerful Stäubli six-axis TX200L HE shows its best side handling 80-kilogram cheese wheels.