- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

FOOD INDUSTRY

Robots for protein processing

Cold, damp environments and dangerous, repetitive tasks. This is what everyday work in meat processing looks like today – but Stäubli is providing remedies. Thanks to robotic automation, throughput as well as output quality can be noticeably increased. At the same time, we create better working conditions in an industry threatened by labor shortages.

Stäubli is a technology pioneer and market leader in the field of protein processing. We offer a comprehensive portfolio of HE robots for processes such as cutting, deboning, portioning, handling of boxes of frozen food as well as unpackaged products.

Main applications from primary processing to packaging

- Meat Processing

- Deboning, Cutting and Packaging

See a detailed overview of individual automated process steps in protein processing here. Thanks to optimal hygienic design, the Stäubli HE series is ideal for operations involving direct contact with meat.

In the cutting process, the TX2-160 HE and TX2-200 HE robots can be used for processes such as pre-cutting, belly opening, cutting, neck cutting and belly lard removal

Conveying through cooling station

Unhooking of the pork halves and positioning on the cutting belt with X-ray system

Front and back end cutting with two TX2-140‘s

Middle part splitting and transport in intralogistic trays for further processing

An autonomous Stäubli AGV forklift delivers the pork primal cuts to further processes or directly to the shipping area

Find out more about automation options for deboning, cutting and packaging in protein processing. Whether primary or secondary packaging, Stäubli robots for the food industry handle every task hygienically, safely and efficiently.

An autonomous counterbalanced stacker from Stäubli WFT brings the pallets from the cold store to the line for further processing

At the beginning, a TX2-160 HE takes the products from the pallet boxes and loads the deboning line

A 3D vision system determines the bone position and the TX2-160 HE precisely detaches the meat from the bone

Meat water jet portioning handled by TX2-140 HE

In primary packaging, the TS2-80 HE packs the cut products into thermoformed trays

Tray sealing station

A TS2-80 with food grade, NSF H1 oil takes over the secondary packaging

After closing the carton, the products are ready for shipment

Finally, a TX2-200 stacks the filled and sealed boxes on pallets

An autonomous Stäubli AGV forklift drives the pallets to further processes

Success stories

-

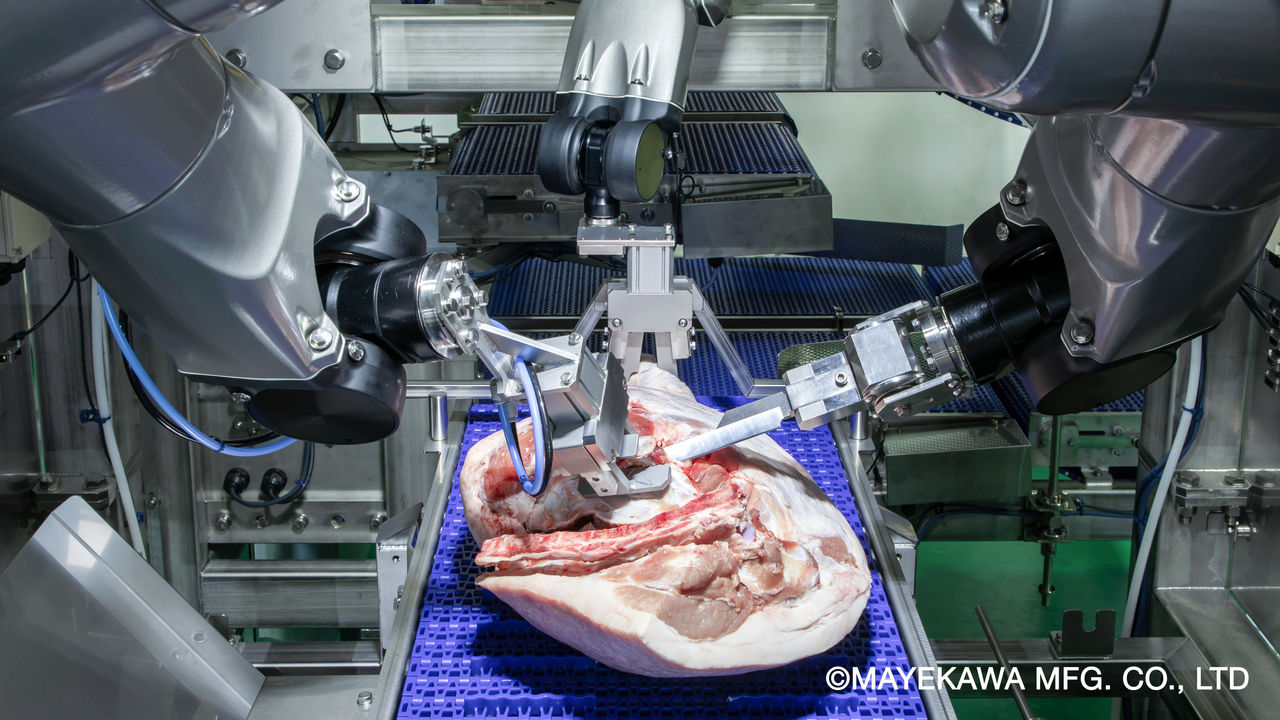

Deboning pork with robots and AI

A new fully automated system for deboning the hip bone and tailbone of a pork leg takes around 40 seconds. The main work is done by three hygienic Stäubli robots: Two hold the leg in place, while the third wields the knife. -

loading slicer with sausages

Supermarket chain uses a large Stäubli six-axis robot to load a sausage slicing and packaging machine at its processing facility in Heilbronn, Germany. A world premiere that relieves the workload on employees and brings many other benefits. -

Skewering and packaging

The packaging of meat kebabs is a strenuous and monotonous task, but this is not the only reason there is hardly any staff for this type of work. With a new system, Busch & Busch is turning the tide and using Stäubli HE food grade robots for packaging. -

Picking and skewering

At its production facility in Morahalom, Hungary, Beltaste N.V. mass-produces kebabs. What makes this factory so special is the unique, fully automated Pick & Skewer line which exemplifies “Food Processing 4.0” - the fourth generation of manufacturing technology. -

Automated sorting and stacking at fish auctions place

The port of Guilvinec is one of the most important in all of France and has recently become perhaps one of the most advanced in the world. In the auction hall, two Stäubli TX200 HE robots handle the fully automated picking of freshly caught fish.