- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

Optimum curd preparation for all capacities

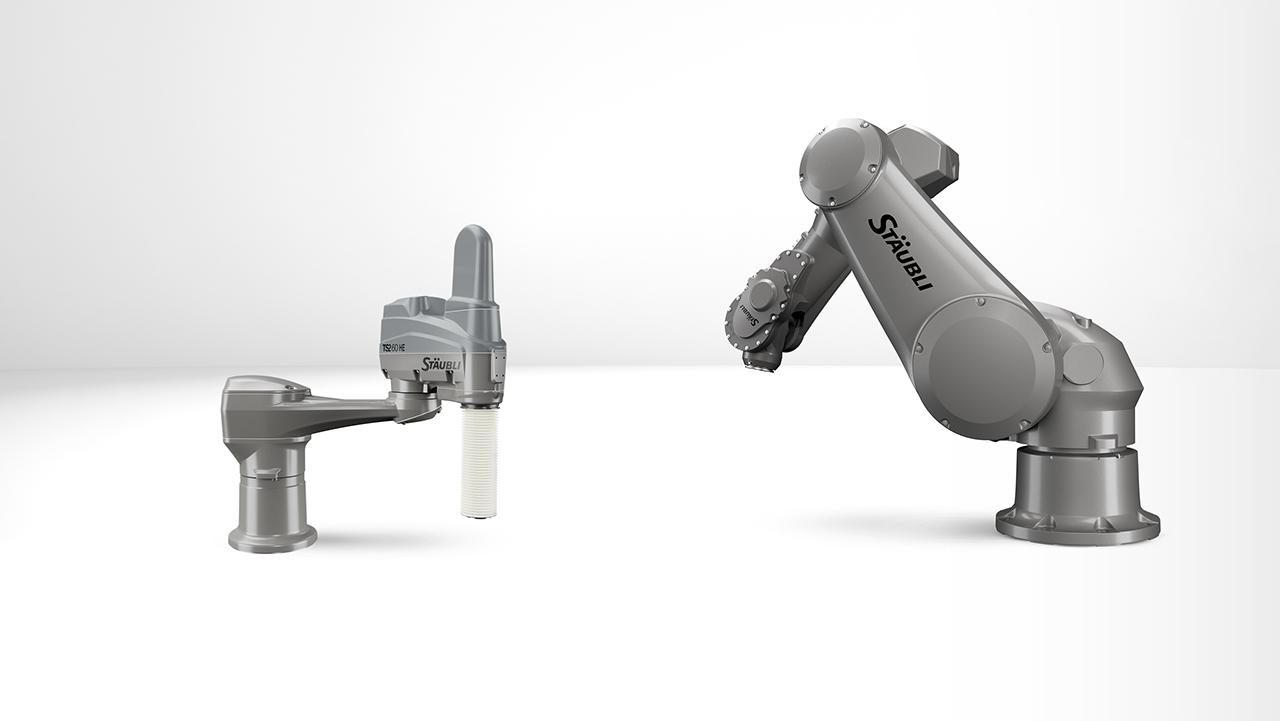

ALPMA has developed a “bassine technology” for producing soft cheese. The special shape of the plastic vats, combined with a patented cutting process using a TX200 HE robot, slices curd with very little waste.

Bassine systems for the production of soft cheeses have been part of the ALPMA product range for severalyears now, as an alternative to the coagulator. ALPMA supplies this ‘bassine technology’ primarily to customers with low to medium output.

The special form of the plastic vats, combined with the patented cutting process by means of robot, enables curd cutting with a very small amount of waste. The insulating plastic ensures low temperature gradients of the milk, thus permitting regular souring and clotting.

Due to the fact that individual rows of vats can be shut down and the processing stations can be moved, there is a high degree of flexibility with regard to pre-ripening, coagulating, syneresis and agitation times.

While the Coagulator can achieve high yields and capacities of up to 50,000 l/h, the Bassine-System’s strengths lie in the preparation of small batches and use in dairies with limited space. Its flexible and parallel strands mean that wide rooms can be optimally used.

By combining the Bassine-System with the proven ALPMA filling technologies, ranging from the AFE to the high-capacity filler MR, you guarantee your product an exact dosage and clean portioning.

The Bassine-System from ALPMA servi: automated polyethylene vats with a capacity of 150 to 670 l will round off ALPMA’s range of curd preparation equipment with a capacity of 2,000 to 30,000 l/h.