- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Robotic tool changers: A revolution in industrial process automation

1. Primer

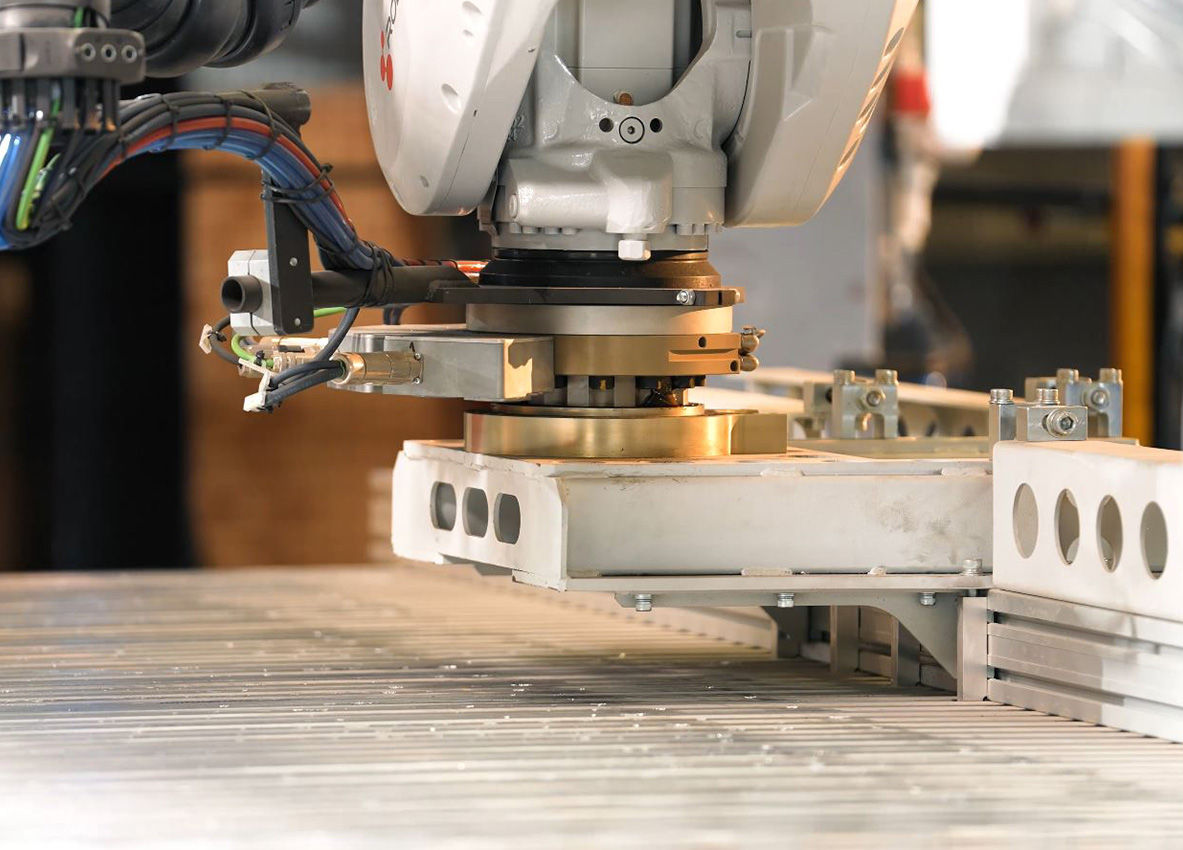

Tool changer systems are the robotic parts of a plant that enable quick and efficient changing of tools. These quick-change systems, also known as tool changers (TCs) have a key role in automating industrialized manufacturing processes. Situated at the interface between the robot arm and the tool (end effector), they enable automated swapping between various process end equipment. This makes it possible to increase the degree of automation, boost productivity, and reduce personnel costs at the same time.

Robot tool changers enable multifunction technology applications where the specific design can be precisely tuned to the requirements of the application. Tool changer systems can access a tool magazine directly. The tool magazine is equipped with suitable end-of-arm tools such as welding guns, drill drivers, spindles for drilling and milling, deburring tools, grippers or vacuum effectors to suit the particular application. The robot can then automatically access the right tool as needs dictate.

2. The role of robotic tool changers

Automatic tool changers have made a significant impact on the development of industrial process automation. As manufacturing processes became increasingly automated, tool changer systems have enabled seamless swapping of end effectors without costly machine downtimes or human interventions, which are inevitably subject to error.

Precision, speed, and flexibility play an ever-increasing role in global manufacturing competitiveness. Robotic tool changers have the potential to lower manufacturing costs while sustainably increasing quality. This gives businesses the chance to create a crucial competitive edge.

The role of industrial tool changers will continue to grow in the future. Modern tool changer systems handle not just the tool change itself, they also have numerous component connection solutions to media lines, data lines, and energy lines. These include, for example, pneumatic lines, vacuum lines, cooling modules, signal lines, servo power, and primary electrical lines.

Efficiency increases thanks to automated tool changers

Seamless, automatic tool changes play a key role in industrial production when it comes to efficiency. The more often tools change, the quicker the investment in an automatic tool changer pays for itself. Robot systems with numerous differing applications are being equipped with fully automated tool changes more and more today.

Robotic tool changers – An overview of applications

In principle, robot tool changers can be used in any manufacturing or handling process with the potential for automation. The industry spectrum is diverse and ranges from joining and connection processes such as welding or screw fitting in process engineering to assembly and machining tasks in the automotive industry and the handling of sensitive components in the aviation industry.

The following list shows an excerpt of the most important applications and their respective advantages for robot tool changers.

- Precision in assembly processes

- Fully automated welding

- Versatile component handling

Automating assembly processes in the manufacturing industry is a demanding task, thanks to the great number of different tasks the robot must perform. Assembly processes often feature small batch sizes, complex motion sequences, and precisely coordinated contact forces. Robot tool changer systems have the potential to significantly increase the degree of automation of assembly lines. Fully automatic swapping of end effectors for parts handling or finishing can generate considerable savings potential. Meanwhile, this frees up personnel resources and prevents human error.

Technological developments in the automotive industry have deeply impacted the automation of welding. As early as the 1980s, the automotive industry recognized the potential of robotic welding and succeeded in integrating suitable tool changers into chassis production. Though it was a slow, step-by-step process, the industry successfully automated the time-consuming, error-prone welding tasks on automotive frames and chassis. This development has continued up to the present day and has become established in many other industries.

Modern robot systems can now weld more efficiently, precisely, and rapidly than human workers, provided the application is standardized. Custom-configurable tool changer systems make it possible to further increase the level of automation in these welding tasks, thereby increasing flexibility in the manufacturing process.

Picking, moving, placing: Component handling is a key task in automated production lines. Since each component differs concerning shape, material, and weight, the end-of-arm tools (EOATs) need constant changing. Special changer systems, for example, are used for this purpose, which can independently switch between different gripper systems with different components, such as parallel grippers, angular grippers, or needle grippers. This significantly increases the precision, efficiency, and productivity of component handling. Variable component manufacturing

Automated quick-change systems can cover a very wide range of tasks. The tool changer system can be customized to customer-specific requirements. The performance, material quality and connection options of such customized tool changer systems can be tailored to the process requirements. In these cases, transfer modules can be seamlessly integrated to carry all different kinds of media and energy.

3. Advantages of robotic tool changers

The integration of modern tool changing systems into robotic production lines has had advantages. These are not limited to economic aspects, but also include occupational safety and sustainability. The most important reasons for using robot tool changers are:

Higher productivity

The automated changing of tools on robotic systems allows for efficient swapping between different tools. This approach minimizes downtime, optimizes production processes. And makes robots more versatile. Depending on the number of tool changes required, considerable increases in productivity can be achieved.

Cost savings

The use of robot tool changers not only generates direct cost savings thanks to needing fewer robots but it also has numerous economic side effects. The higher process efficiency when using tool changers makes it possible to significantly increase the level of robot utilization.

Industrial safety

Manually changing robot tools poses a potential accident risk, even when carried out by qualified and experienced personnel. In addition, the repetitive changing of end effectors can cause high ergonomic strain in the long term. Robot tool changing systems relieve human personnel of these potentially harmful activities and reduce the risk of accidents to a minimum.

Flexibility and adaptability

Modern production lines must continuously adapt to changing customer requirements. Robot tool changers allow a company to make these adjustments with startling efficiency. Thanks to standardized interfaces between the robot flange and the end effector, the robot's range of tasks can be flexibly adapted in no time.

4. Robotic tool changers in practical use

Highly automated production lines with intelligent, technologically advanced robots have been a driving force in industrial production for many years. With impressive precision, speed, and agility, robotic systems now work hand in hand with humans or are even fully automated. In our video, we use impressive, practical examples to show you how robot systems can perform a wide and variable range of tasks with the help of state-of-the-art tool changers.

5. Frequently asked questions about robotic tool changers

How can robot tool changers be customized to specific manufacturing requirements?

Modern tool changer systems can be tailored to customer-specific requirements and applications. The tool changer can be configured in a modular way to create customized solutions based on proven system components. As a result, customers benefit from individual solutions perfectly tailored to their needs.

In which industries are robot tool changers used most frequently?

Robot tool changers are mainly used in the automotive industry, aerospace, electronics manufacturing, metalworking and plastics processing. In addition to the above, tool changers have also become established in other industries, such as the chemical and pharmaceutical industry, the food industry, and many others that feature production processes

6. Summary: Sustainable productivity gains thanks to robotic tool changers

The use of robots in industrial production lines is already widespread in many industries. Strongly production-oriented companies have recognized that robotics is central to ensuring sustainable competitiveness in a globalized market.

Yet, so much potential for further automating industrial manufacturing processes remains. Automated tool changer systems play a key role here: They can significantly expand the range of applications for robotic solutions, thereby improving productivity, efficiency, quality, and industrial safety. In particular, the possibility of modularly designed robot tool changers according to customer requirements offers significant potential.

Are you interested in robot tool changers? Feel free to get in touch

More topics in focus

Our topics serve as your comprehensive resource for understanding the critical role of robot tool changers in enhancing efficiency across a multitude of applications.

Discover our innovative solutions - Download exclusive brochures now!

Stäubli is a leading technological pioneer in the construction and development of robotic tool-changing systems solutions.

Discover the versatility and efficiency of Stäubli's advanced robotic tool-changing systems by downloading our showcases of innovative solutions.

Success Stories

Find out our solutions and customer testimonials!

-

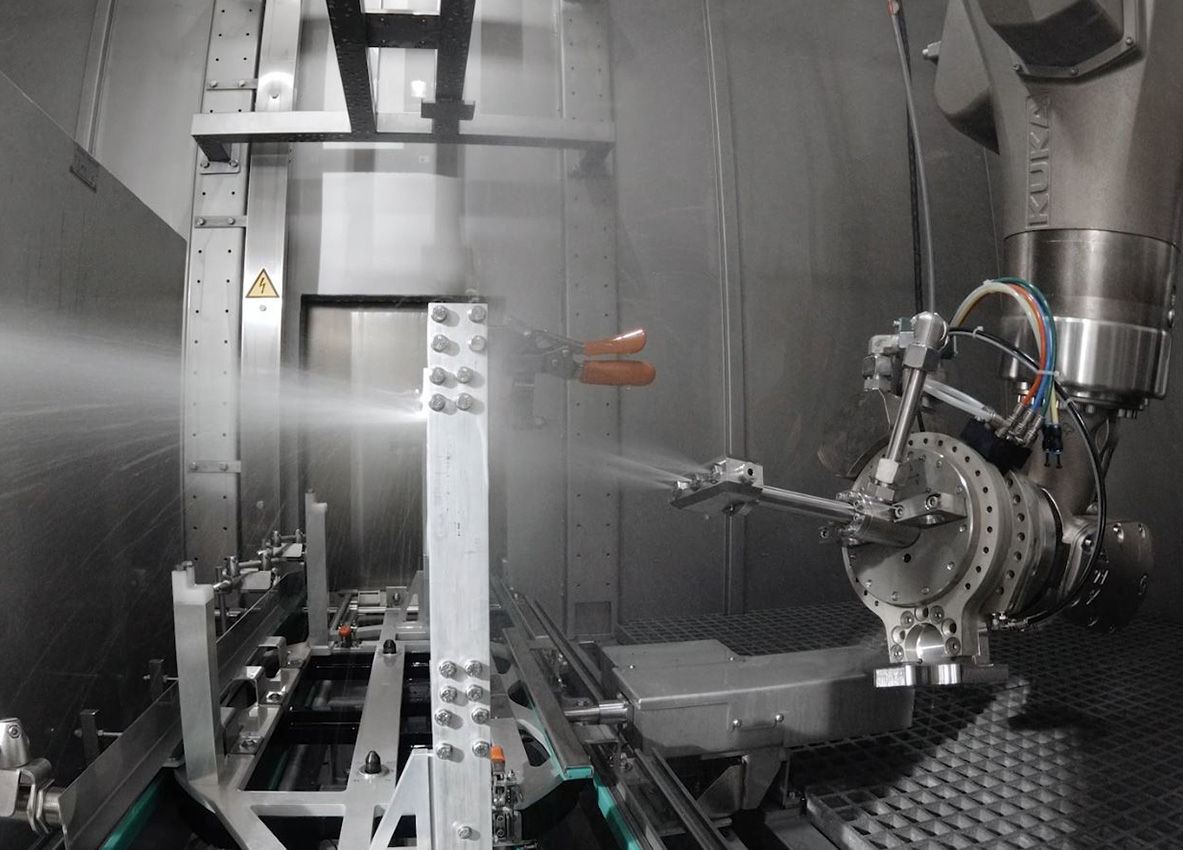

Silberhorn - Industrial Machinery

Component cleaning for metalworking in the tightest of spaces - Robot tool change in the wet cell. -

Volvo Trucks - Automotive

Provide robot tool change systems which meet Volvo’s demanding reliability target. -

Robinova / Teksan - Industrial Machinery

A field proven solution which saves time, improves robot utilization, and enhances operator safety. -

Miele - Industry Machine & Equipments

Miele opted for the modularity and efficiency of the MPS 130 systems with the Stäubli robots to develop their dishwasher lines production.