食品産業

食肉産業用途に適したロボット

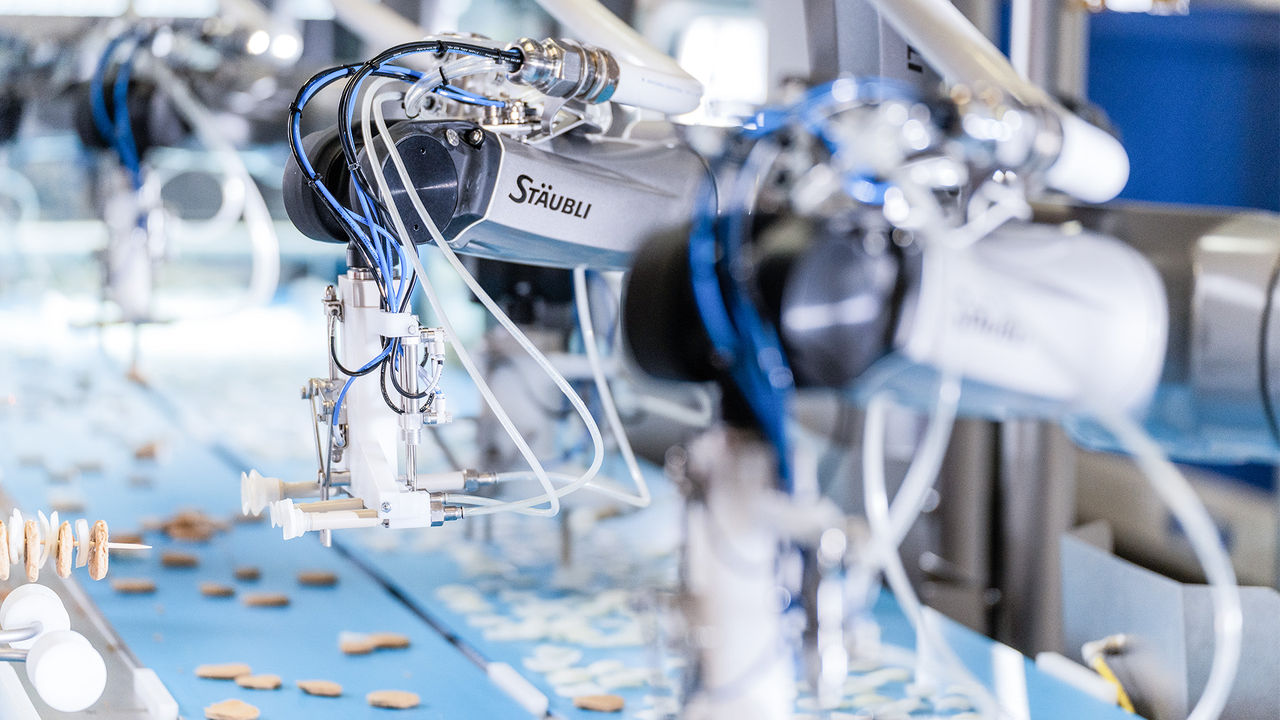

低温の高湿度環境で行われる危険で反復的な作業-これが今日の食肉加工の仕事の姿です。しかし、ストーブリはソリューションを提案します。ロボットを用いた自動化によって、処理能力と製品の品質を大きく向上させます。同時に、労働力不足に悩む産業には、より良い労働条件を提案します。

ストーブリは、食肉加工分野における技術の先駆者であり市場リーダーです。切断、除骨、分配、凍結食品の箱詰め、裸製品の取り扱いなどに最適なHEロボットのラインアップがそろっています。

一次工程から包装までの主要なアプリケーション

- 食肉加工

- 徐骨、カット、包装

こちらで食肉加工の様々なプロセスの自動化の詳細をご覧いただけます。最高水準の衛生的設計要件を満たすストーブリHEシリーズは、食肉を直接扱う操作に最適です。

切断プロセスでは、TX2-160 HEおよびTX2-200 HEロボットは、プレカット、腹開き、切断、首の切断、腹ラードの除去などのプロセスに使用できます

冷却ステーションによる搬送

豚肉の半分のフックを外し、X線システムを使用してカッティングベルトに位置決めします

2台のTX2-140によるフロントエンドとバックエンドの切断

中間部の分割とイントラロジスティックトレイでの輸送、さらなる処理

自律型のストーブリAGVフォークリフトは、豚肉の原産地を次のプロセスに配送するか、直接出荷エリアに配送します

Find out more about automation options for deboning, cutting and packaging in protein processing. Whether primary or secondary packaging, Stäubli robots for the food industry handle every task hygienically, safely and efficiently.

An autonomous counterbalanced stacker from Stäubli WFT brings the pallets from the cold store to the line for further processing

At the beginning, a TX2-160 HE takes the products from the pallet boxes and loads the deboning line

A 3D vision system determines the bone position and the TX2-160 HE precisely detaches the meat from the bone

Meat water jet portioning handled by TX2-140 HE

In primary packaging, the TS2-80 HE packs the cut products into thermoformed trays

Tray sealing station

A TS2-80 with food grade, NSF H1 oil takes over the secondary packaging

After closing the carton, the products are ready for shipment

Finally, a TX2-200 stacks the filled and sealed boxes on pallets

An autonomous Stäubli AGV forklift drives the pallets to further processes

サクセスストーリー

-

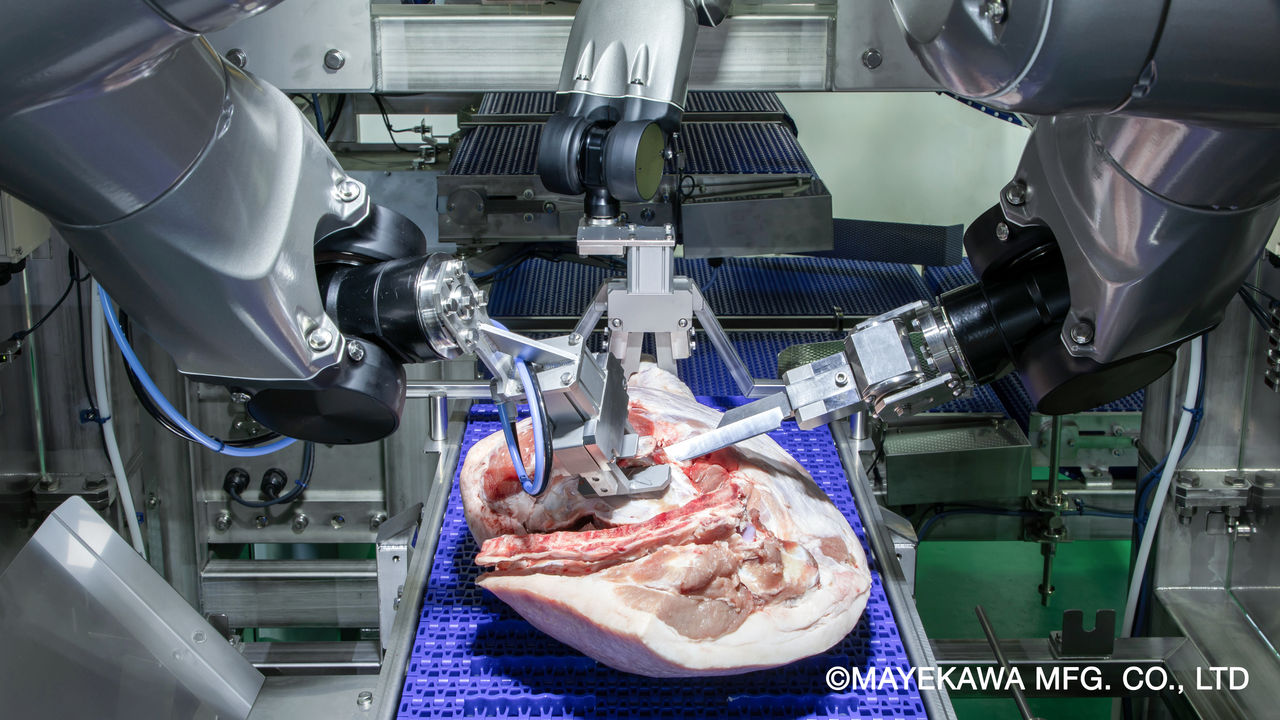

ロボットとAIによる豚肉の骨抜き

豚足の腰骨と尾骨を骨抜きにするための新しい全自動システムは、約40秒かかります。主な作業は、3台の衛生的なストーブリ製ロボットによって行われ、2台が脚を固定し、3台目がナイフを振り回します。 -

ソーセージでスライサーをロードする

あるスーパーマーケットチェーンは、ドイツのハイルブロンにある加工施設で、ストーブリの大型6軸ロボットを使用してソーセージのスライスと包装機を積み込んでいます。社員の負担を軽減し、その他多くのメリットをもたらす世界初披露。 -

串打ちと包装

肉のケバブの包装は骨の折れる単調な作業ですが、この種の作業にスタッフがほとんどいない理由はこれだけではありません。Busch & Buschは、新しいシステムにより、ストーブリHE食品グレードのロボットを包装に使用し、流れを変えようとしています。 -

ピッキングと串刺し

ハンガリーのモラハロムにある生産施設では、Beltaste N.V.がケバブを大量生産しています。この工場を特別なものにしているのは、第4世代の製造技術である「食品加工4.0」を体現する、完全に自動化されたユニークなピック&串ラインです。 -

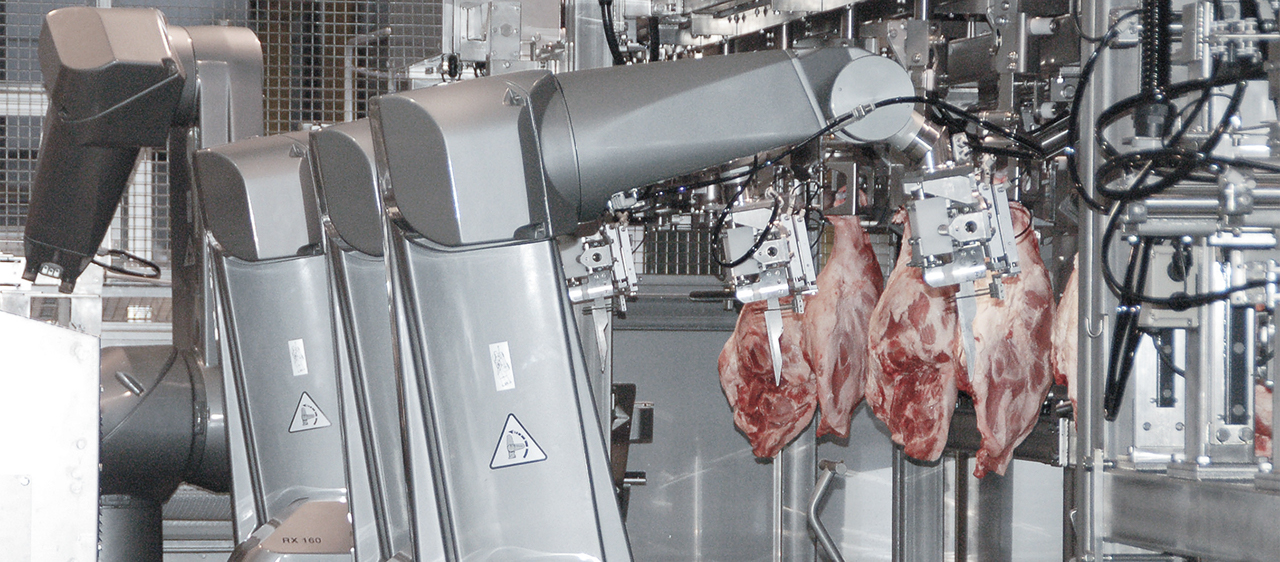

ロボットによる骨抜き

日本企業の前川は、食品業界向けの最先端の技術ソリューションを設計しています。同社は、統合されたハム脱骨システムのために、食品基準を満たすストーブリRX160 HE 6軸ロボットを選択しました。 -

魚の競り場での自動仕分けと積み上げ

ギルヴィネック港は、フランス全土で最も重要な港の1つであり、最近ではおそらく世界で最も進んだ港の1つとなっています。オークション会場では、ストーブリの2台のHEロボット「TX200」が、獲れたての魚を全自動でピッキングします。